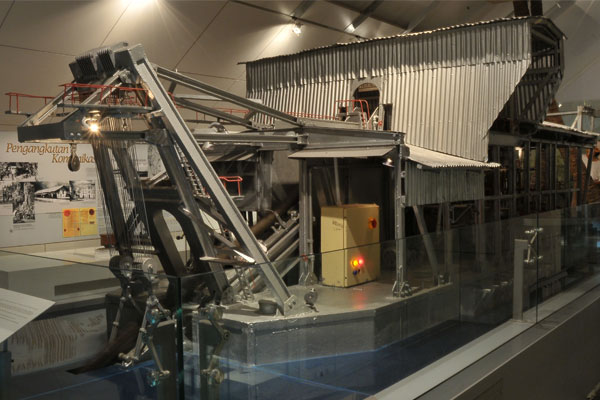

A dredge resembles a floating factory, with a flat bottom, sides and a roof on an artificial lake. It carries a chain of heavy buckets to scoop out the alluvial tin and transport it to the body of the dredge. The excavated material is broken up by jets of water as it falls on to the revolving screens. The tin bearing material passes to a primary separating plant, while large stones and rubble are retained by the screens. The largest dredge can dig in a continuous operation to depth of 200 meters below water level and can handle over three quarter of a million cubic meters of material per month. The first tin dredge was introduced by Malayan Tin Dredging Ltd in the Kinta Valley tin field in 1913. By 1940, 123 dredges were in operation and this was the highest total number of dredges ever recorded in the country. This number began to diminish by 1981 and by the end of 1983 there were only 38 dredges left. Presently, there is not a single dredge in operation.